Railway Wheel Forgings & Manufacturing

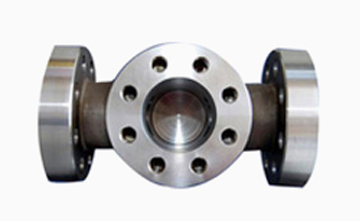

FLANGES

The ASME B16.5 – 1996 Pipe Flanges and Flange Fittings standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings for pipe flanges and flanged fittings.

The standard includes flanges with rating class designations 150, 300, 400, 600, 900, 1500, and 2500 in sizes NPS 1/2 through NPS 24, with requirements given in both metric and U.S units. The Standard is limited to flanges and flanged fittings made from cast or forged materials, and blind flanges and certain reducing flanges made from cast, forged, or plate materials. Also included in this Standard are requirements and recommendations regarding flange bolting, flange gaskets, and flange joints.

DIN PN6 Flanges is designed to operate at up to 6 levels. While different grades may be used in the manufacture of DIN Standard Flanges, the most common materials include carbon steel, alloy steel and several different grades of stainless steel alloys. In comparison to most stainless steel grades, the Carbon Steel DIN Flange tends to cost lesser due to its low alloying cost. On the other hand, although the cost of Stainless Steel DIN PN40 Flanges is much higher, the alloys offer better corrosion resistance and mechanical properties while having excellent performance across a wide area.

FORGED FITTINGS

The forged pipe fittings are suitable for fire fighting, HVAC, Oil & Gas Industries, Petrochemicals, High Pressure Lines, Railways, Shipping, Steel Plants, Boilers, Steam. Chemicals and Other Industrial Purposes. The fittings are tested for leakage at an internal hydraulic pressure of up to 1000 lbs, 3000 lbs & 6000 lbs. Forged Pipe Fittings are available in Socket Weld and Screwed / Threaded forms ranging from 0.25 Inches Through 3.00 Inches.

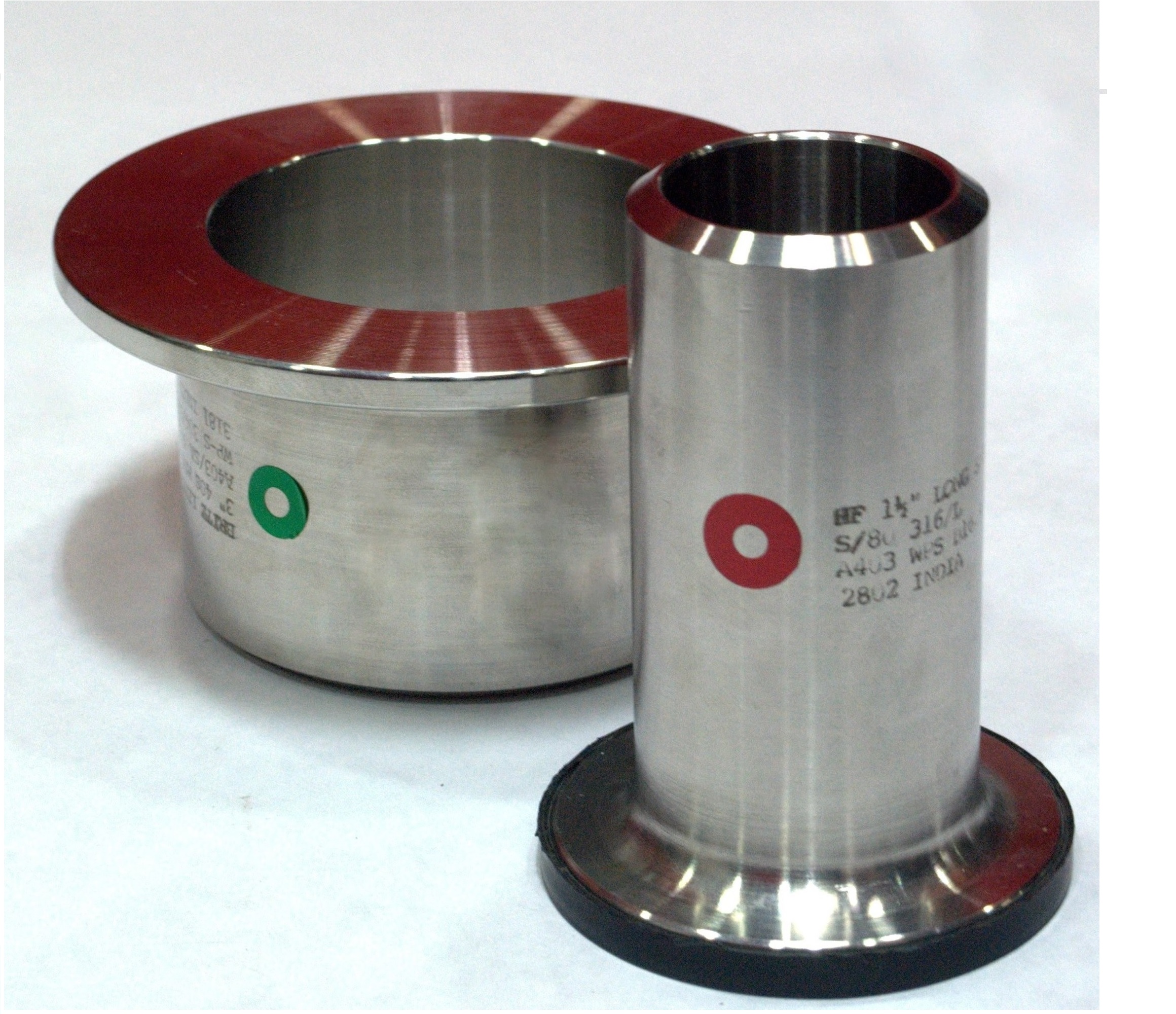

STUB ENDS

Forged stub ends are pipe fittings used to provide a flange-like connection in a piping system. They are specifically designed to be used with lap joint flanges, which slide over the stub end and are then rotated for alignment with other flanges.

The “forged” part of the name indicates that these fittings are created using the forging process, which enhances their strength and structural integrity through the application of high heat and pressure to the metal. Forging typically results in a product with improved mechanical properties and resistance to impact and fatigue.

Forging stub ends are available in long and short pattern lengths and in a variety of materials to match the pipe system they are used in, such as stainless steel, alloy steel, carbon steel, etc. They are advantageous because they make the line easy to disassemble for inspection, cleaning, or quick modification.

These fittings are often used in systems that require frequent dismantling for inspection and cleaning, and in applications where there is a need for a rotationally aligned system. They find extensive use in various industries, including petrochemicals, oil and gas, and water treatment plants.

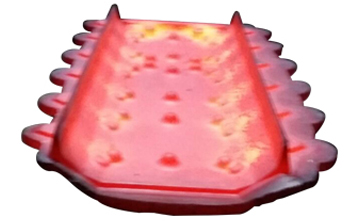

CHRISTMAS TREE COMPONENTS

We provide a flawless range of Bonnets to our clients available in numerous designs to fit the different requirements. These products are manufactured using quality raw material sourced from trusted vendors. We also offer customization solutions according to the need of the customer.

TOP DECK

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.